Week 2 Update

Hi everyone! This is Jace and Juan, your mechanical leads.

This week, the mechanical subteam has been hard at work building and testing out their prototypes for different mechanisms, assembling the drivetrain, and manufacturing parts for the Rainbow Robotics building kits. Here is a quick recap of everything!

Prototyping

Hopper

Based on the archetype discussion, we decided to have a hopper mechanism in order to store FUEL. The numerical goal for the hopper was holding 30 or more fuel.

Based on testing data, we found out that 3.5” spacing between belts and a flat orientation worked the best. It also successfully held 30 fuel.

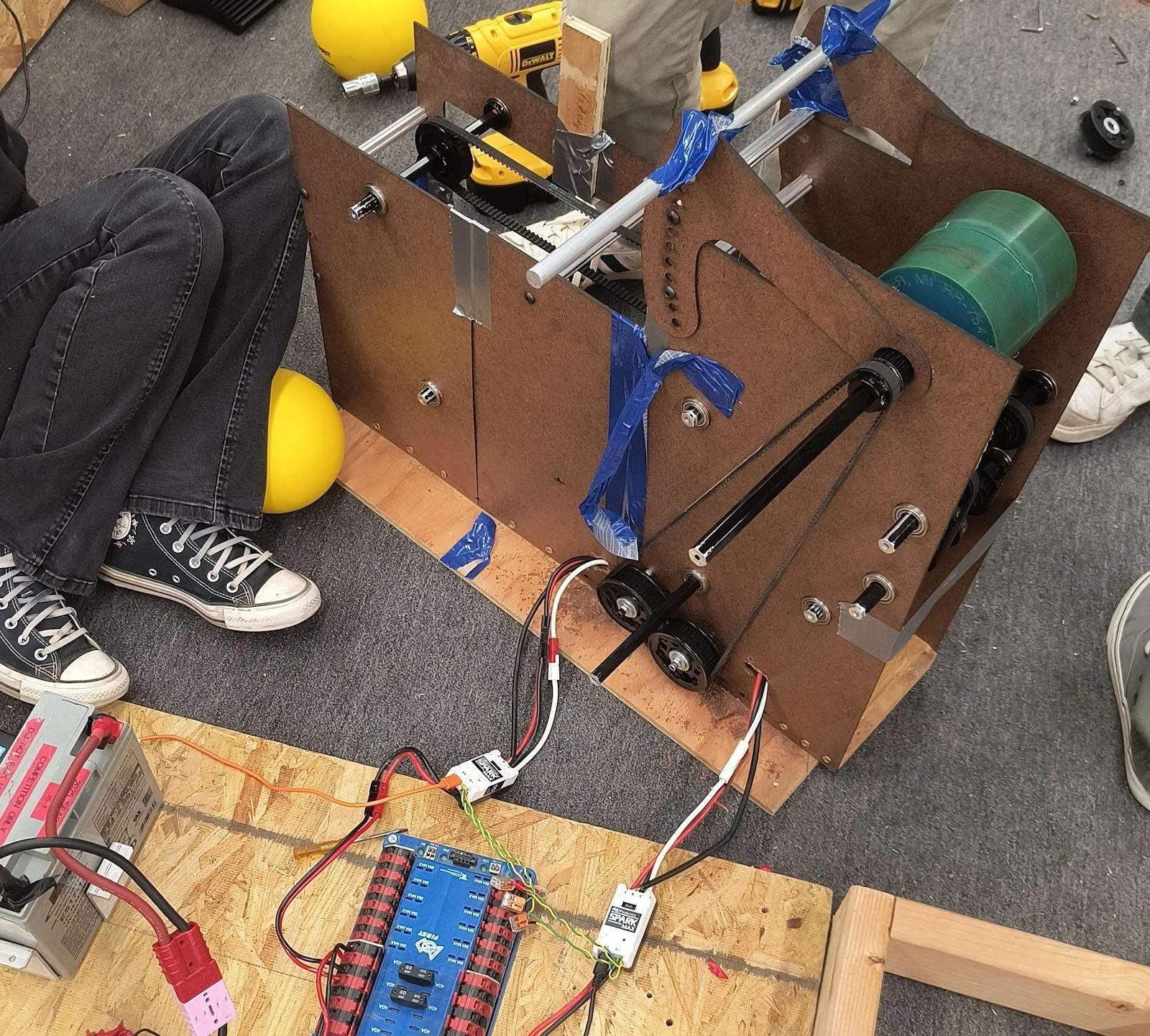

Shooter

We tested two different types of shooter prototypes: a hooded shooter and a two-wheeled shooter. Both types of shooters showed success based on the data: the two-wheeled shooter could reach 8 FUEL per second with 0.5 compression between the shooter wheels. The fire rate of the hooded shooter is currently being tested with the indexer.

Indexer

We decided that the robot will need an indexer in order to get the FUEL from the intake to the shooter. The indexer group attached their prototype to the hooded shooter prototype and added flywheels in order to test them together with different RPMs. The prototype needs further testing at future meetings, but is showing success at transferring the FUEL.

Climb

Three groups were able to put together some climb prototypes. The elastic climb prototype that was inspired by Penn State Ri3D could hold up to 145lbs. The most recent version of the wood climb prototype held roughly 135lbs. The wood climb is also capable of climbing from the side of the TOWER rungs.

Wood Climb #1

Wood Climb #2

Elastic Clim

Intake

In order to intake the fuel into the robot so we can score, we’ve been working on a prototype to finalize the geometry of our intake. It’s gone through several iterations and has proven very effective.

Drivetrain Assembly

Additionally, we started the manufacturing and assembly of our drivetrain. All 4 MK5i swerve modules were assembled, and were put together using the drivetrain tubes we milled with the help of our sponsor, Valley Robotics Program. The next step is to rivet the belly pan, and wire the drivetrain so that it can be handed off to the programmers!

Rainbow Robotics Manufacturing

Some members were also manufacturing the parts for the building kits we will use for Rainbow Robotics outreach events. Balancing tasks for the robot and Rainbow Robotics was a fun challenge, but with teamwork, we were able to get everything done for the upcoming events next week. The mechanical team will continue to collaborate with the business team to design and manufacture more outreach event activities. Keep an eye out for more Rainbow Robotics updates!

Goodbye for now!

We’ve got a look of work ahead of us, but we’re excited to see all we’ll accomplish in the next couple of months. See you next time!